Oct 19, 2022

Version 1

Monitoring the point spread function for quality control of confocal microscopes V.1

- Glyn Nelson1,

- Ioannis Alexopoulos2,

- Maria Azevedo3,

- Fabio Barachati4,

- Yury Belyaev5,

- Mariana T Carvalho6,

- Yann Cesbron7,

- Aurelien Dauphin8,

- Alexander D Corbett9,

- Laurent Gelman10,

- Nadia Halidi11,

- Xiang Hao12,

- Hella Hartmann13,

- Rainer Heintzmann14,

- Peter Hemmerich15,

- Marcel Kirchner16,

- Judith Lacoste17,

- Penghuan Liu18,

- Laure Plantard19,

- Claire A Mitchell20,

- Tobias Müller21,

- Kees van der Oord22,

- Alex L Payne-Dwyer23,

- Santosh Podder24,

- Rachid Rezgui25,

- Sandra Ritz26,

- Stanley Schwartz27,

- Michael J Shaw28,

- Tse-Luen Wee29,

- Roland Nitschke30,

- Orestis Faklaris31,

- Ian M Dobbie32

- 1Newcastle University, BioImaging Unit, UK;

- 2Multiscale Imaging Platform, Institute for Lung Health, Justus Liebig Universität Gießen;

- 3i3S – Instituto de Investigação e Inovação em Saúde, University of Porto, Portugal;

- 4PicoQuant GmbH;

- 5Microscopy Imaging Center (MIC), University of Bern, Bern, Switzerland;

- 6INL - International Iberian Nanotechnology Laboratory;

- 7Institute of Science and Technology Austria, Klosterneuburg, Austria;

- 8Unite Genetique et Biologie du Développement U934, PICT-IBiSA, Institut Curie, INSERM, CNRS, PSL Research University, Paris, 75005, France;

- 9University of Exeter;

- 10Friedrich Miescher Institute for Biomedical Research;

- 11Centre for Genomic Regulation;

- 12Zhejiang University, Hangzhou 310027, China;

- 13TU Dresden, CMCB;

- 14Leibniz Institute of Photonic Technology;

- 15Leibniz Institute on Aging, Core Facility Imaging, Jena, Germany;

- 16Max Planck Institute , Koln;

- 17MIA Cellavie Inc.;

- 18College of Optical and Electronic Technology, China Jiliang Univeristy, Hangzhou, China;

- 19Friedrich Miescher Institute for Biomedical Research, Basel, Switzerland;

- 20Beatson Advanced Imaging Resource, The Beatson Institute for Cancer Research, Glasgow, UK;

- 21IMP, Vienna;

- 22Nikon Europe BV;

- 23School of Physics Engineering and Technology, University of York, UK;

- 24Indian Institute of Science Education and Research (IISER) Pune;

- 25New York University, Abu Dhabi;

- 26Institute of Molecular Biology gGmbH (IMB);

- 27ISO International Standards Organization TC172 SC5;

- 28National Physical Laboratory;

- 29Cold Spring Harbor Laboratory;

- 30Life Imaging Center, University of Freiburg, Germany;

- 31MRI, Biocampus, University of Montpellier, CNRS, INSERM, Montpellier, France;

- 32Johns Hopkins University

- QUAREP-LiMiTech. support email: info@quarep.org

External link: https://quarep.org/

Protocol Citation: Glyn Nelson, Ioannis Alexopoulos, Maria Azevedo, Fabio Barachati, Yury Belyaev, Mariana T Carvalho, Yann Cesbron, Aurelien Dauphin, Alexander D Corbett, Laurent Gelman, Nadia Halidi, Xiang Hao, Hella Hartmann, Rainer Heintzmann, Peter Hemmerich, Marcel Kirchner, Judith Lacoste, Penghuan Liu, Laure Plantard, Claire A Mitchell, Tobias Müller, Kees van der Oord, Alex L Payne-Dwyer, Santosh Podder, Rachid Rezgui, Sandra Ritz, Stanley Schwartz, Michael J Shaw, Tse-Luen Wee, Roland Nitschke, Orestis Faklaris, Ian M Dobbie 2022. Monitoring the point spread function for quality control of confocal microscopes. protocols.io https://dx.doi.org/10.17504/protocols.io.bp2l61ww1vqe/v1

Manuscript citation:

https://www.protocols.io/edit/monitoring-the-point-spread-function-for-quality-ccsuswew/

License: This is an open access protocol distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Protocol status: Working

We use this protocol and it's working

Created: July 06, 2022

Last Modified: March 17, 2023

Protocol Integer ID: 66100

Keywords: PSF, bead, resolution, FWHM, Quality Control, Confocal, Microscopy

Disclaimer

This protocol was developed by the members of QUAREP-LiMi Working Group 5. The member list can be found here: (hhttps://quarep.org/working-groups/wg-5-iso-lateral-and-axial-resolution/)

The QUAREP-LiMi is a group of scientists interested in improving quality assessment (QA) and quality control (QC) in light microscopy. We first came together on April 2020 and as of October 2022 the group has grown to 456 people from 34 countries spread around the world. We have members from academia, microscopy communities, companies, organizations or institutions related to standardization, scientific publishers, and observers from funding agencies.

Abstract

This protocol focuses on measuring the microscope's lateral and axial resolution, essential for reporting size measurements of near-resolution limit objects or distances between them. Here resolution is expressed as the Full Width at Half Maximum (FWHM) of a measured Point Spread Function (PSF) of sub-resolution size beads. PSF is highly related to objective quality and condition, but also depends strongly upon other parameters ranging from sample preparation to signal detection. Monitoring PSF over time will identify possible aberrations in the system (e.g., damaged, unclean objective, defective or not adapted oil, etc.). We define test sample preparation, image acquisition, and data analysis protocols for point scanning and spinning disk confocal microscopes.

Guidelines

Assumption: This method describes the image capture, assuming you use 175 nm beads and a high NA oil-immersion objective.

Alternative pre-prepared bead samples are available and can be used to obtain reliable PSFs e.g. Tetraspeck (T14792, Thermofisher) and PSFcheck (https://www.psfcheck.com/). We have chosen to prepare fresh bead samples in this protocol to maximise brightness, stability, and availability.

Materials

- 175 nm Green-Yellow beads (ThermoFisher, P7220)

- Coverslips #1.5H, (high quality number 1.5 (170 +/- 5 nm), e.g., Marienfeld 22x22 mm Cat No. 0107052)

- Microscope slides, uncoated

- Blunt ended forceps

- Clean bench or laminar flow hood for sample preparation

- Whatman 3M lens cleaning paper, or other lint free lens tissue

- Reverse osmosis (RO) H2O or double-distilled H2O

- HCl 1M, made with double distilled or RO H2O

- 100% (absolute) ethanol - ultra-pure, Analytical grade or Gas chromatography grade

- Picodent Twinsil22 (Picodent twinsil®, picodent, Dental Produktions- und Vertriebs GmbH) or Polysil 3481 silicone (Polysil Ltd), for sealing.

Safety warnings

Ensure you follow general lab safety guidelines for radiation sources and chemicals as outlined within your organisation.

Laser safety and regulations

- Please refer to the documentation provided by the manufacturer for additional warnings and preventive, protective equipment (PPE) requirements (e.g. laser safety goggles). Always consult your local Laser Safety Officer or Radiation Safety Officer and refer to your laboratory safety documentation for more information.

- You can also consult your Laser Safety Standards ANSI Z136 in North America, SUVA 66049.D in Europe, and BS EN 60825-1 in the UK. Additionally, laser safety standards and regulations are covered by IEC norm 60825-1, and LED eye safety standards and regulations are covered by IEC norm 62471 in Europe.

Safety information

Hazardous, visible, or invisible radiation from lasers, lamps, and other light sources used for microscopy can cause permanent damage to the retina, skin burns, and fire. Always follow proper laser safety protocols for your equipment and situation.

Before start

Bead sample preparation section- this should be done at least two days before starting imaging to ensure suitable curing times for mountant.

Bead image acquisition section- the system should be warmed up for 1 hour before starting to ensure thermal stability to avoid axial drift during imaging.

Bead Slide Preparation

Bead Slide Preparation

2h 7m

2h 7m

Coverslip Preparation

30m

Immerse the coverslip in a beaker with 1M HCl and agitate for 30 min at room temperature.

30m

Rinse the coverslip twice with 250 mL of distilled water and immerse in 100% Ethanol for storage.

2m

Bead dilution

Centrifuge the bead stock solution for a few seconds in a benchtop centrifuge to collect all suspension in the bottom of the tube and then vortex for 2 to 3 minutes.

Note

This long vortexing step is crucial to avoid aggregate formation and get well-distributed beads on the coverslip.

Note

Alternatively, sonication in a water bath for two minutes at room temperature will also help to dissociate aggregates.

5m

Dilute the fluorescent beads in H2O.

Note

For the ThermoFisher 175 nm beads (catalogue number P7220), dilute the green (505/515 nm) bead stock solution 1:2500 as follows:

5 μL of stock solution + 495 μL H2O (Dilution 1), then

20 μL of Dilution 1 + 480 μL H2O (Final solution)

This equates to approximately 1.2 x 106 beads per ml.

Note

The final solution can be made in absolute Ethanol to aid drying with no difference in the final bead images, but this can dim the signal from the beads, and if the drops dry too quickly can leave rings of beads rather than a more even spread.

Note

175 nm beads from Spherotech (catalog number FP-0252-2) can be used as an alternative, however, the batch we tested was 3-4 times dimmer than the ThermoFisher 175 nm beads.

Other bead samples were not tested exhaustively enough to allow a thorough comparison.

If a 488 nm or similar line isn't available on your microscope, use one of the other colours of beads in the P7220 stocks that better matches your microscope.

Take a cleaned coverslip, allow to air-dry, then dispense 10 μl of the bead solution as mini-droplets across the coverslip, ensuring the drops are as small as possible.

Note

The solution is dispensed onto the coverslip (not on the slide) so as to have the beads as close as possible to the coverslip. This improves reproducibility but can be a problem if using a water immersion lens, as the beads may undergo supercritical emission. If this is the case, then suspending the beads in an immersion medium can be used as an alternative, but the user must be aware of potential spherical aberration problems as you image further from the coverslip.

Note

The solution is dispensed in droplets to distribute the beads on the surface of the coverslip.

Let the coverslips with droplets air-dry at room temperature (it takes at least one hour) in a dust-free environment (ideally a laminar flow hood, otherwise under cover, e.g. a tip box lid).

Note

Do not try to speed up the process by putting the coverslip in a hot environment or on a heating plate; if evaporation takes place too fast, rings of beads will form instead of an even spreading.

1h

The bead slide preparation described below contains steps previously published in the following protocols:

CITATION

as well as another:

CITATION

Bead slide mounting

Clean the microscope slides with 100% Ethanol and lens tissue, and allow to air dry.

Place a drop of mounting medium in the centre of a microscope slide. For a 22 x 22 mm coverslip, 12 μL of medium is sufficient.

Note

Choose a mounting medium that matches the microscope objective to be used (e.g. high refractive index (RI) mountant for oil immersion, glycerol for glycerol-immersion, and aqueous medium (e.g. agarose) for water immersion).

Here we describe sample preparation for an oil immersion lens using a high RI curing mountant.

Pay attention to the possibility of supercritical emission if you have a substantially lower RI of medium compared to the coverslip.

Note

Some mounting media are very viscous. It may help to warm them slightly (e.g. 37 °C) and to cut the end of the pipette tip to avoid bubbles when pipetting.

Using forceps, gently take a dried coverslip and place it bead-side down onto the drop of mounting medium in the centre of the microscope slide, lowering down from one side to the other to push the excess medium and potential bubbles towards the opposite edge.

Remove any bubbles and excess mounting medium by covering with lens tissue and pressing very gently. Remove lens paper immediately, taking care not to remove the coverslip with it! Let the mounting medium cure (if required) to reach its optimal refractive index by storing slides in the dark at room temperature.

Note

Prolong Gold requires at least 24h to cure. We recommend waiting for 48h to reach a stable refractive index of 1.46, curing in the dark, laid flat.

Seal the coverslip edge with Picodent dental silicone or other two component silicone (see Materials), ensuring the resulting seal is not so thick that you will be able to focus with large blunt-nosed objectives.

Note

If you need to seal many slides with a fast-setting silicone, pre-cool all material at 4°C and seal slides in a cold room.

Note

Avoid nail varnish as a seal since some chemical interactions can occur between the mounting medium and the varnish components, affecting the RI of the mountant and possibly creating background fluorescence.

The bead slides can be stored at room temperature for 6-12 months.

Note

For longer periods, the background signal may increase and the bead intensity diminish, as shown in Figure 1.

Expected result

Figure 1. Change in fluorescence intensity of beads and surrounding background after 1.5 years of storage in a sealed bead slide at room temperature (Thermofisher P7220 green beads in Prolong Gold). n=9 for both time points. Significantly lower bead intensity and higher background signal were observed once 1.5 years old (Dunn's test, P< 0.001). Acquisitions were taken with a Leica SP8 LSM microscope, with an open pinhole and a 63x/1.4 PlanApo objective as described in this Protocol. Units are expressed as arbitrary fluorescence units taken from raw images (16-bit). Background signal and Bead fluorescence plotted on separate y-axes due to large differences in values.

Bead image Acquisition

Bead image Acquisition

Prepare the microscope system.

Allow the system to warm up, ensuring everything is turned on to allow system stabilisation.

Note

Before starting, ensure that the entire microscope system is warmed up for 1 h prior to imaging, including lasers on and the sample on the stage (NB: some software will switch the lasers off or to standby if unused for 30 minutes or longer. Check the settings, and/or set the microscope to capture a simple time-lapse at low power to ensure the lasers are kept on). Be aware that any problems concerning z-drive accuracy or stage stability can affect the acquired PSF.

Use a high magnification, high NA objective, e.g. 63x/1.4 on point scanning confocal microscopes or 100x/1.4 on spinning disk systems.

Note

The above magnifications and NA are well suited to 175 nm beads but different types of objectives could also be used. Table 1 highlights the theoretical resolution for various high NAs and immersion medium for LSM and Spinning Disk systems.

| A | B | C | D | E | F | G | H | I | J | |

| Point Scanning Confocal | Spinning disk Confocal | |||||||||

| NA | n | λEm | λEx | xy | z | max Bead | xy | z | max Bead | |

| 1.45 | 1.515 | 525 | 488 | 171 | 399 | 110 | 184 | 524 | 175 | |

| 1.4 | 1.515 | 525 | 488 | 177 | 458 | 175 | 191 | 524 | 175 | |

| 1.3 | 1.515 | 525 | 488 | 191 | 582 | 175 | 205 | 524 | 175 | |

| 1.2 | 1.33 | 525 | 488 | 207 | 567 | 175 | 223 | 524 | 200 | |

| 0.8 | 1 | 525 | 488 | 311 | 1073 | 250 | 334 | 524 | 250 | |

| 0.75 | 1 | 525 | 488 | 331 | 1268 | 250 | 357 | 524 | 250 | |

Table 1: Theoretical lateral (xy) and axial (z) Full Width at Half Maxima (FWHM) (in nm) for various common lens NAs with their associated immersion medium refractive indices (n) and recommended maximum bead size (nm) to check system quality for that objective. Values are calculated using the Equations given in MetroloJ_QC. NB bead size recommended is for Quality checks, not system resolution checks (see reference below), and is a trade-off for sample ease of use and broad compatibility across NAs with a robust sample for multiple use/ longevity. Theoretical resolutions were calculated using lateral resolution:

and axial resolution:

CITATION

Clean your objective lens.

Note

It is essential to ensure that the objective is clean, as per manufacturer's recommendations. If not, then the following protocol has been found to work for all manufacturer's objectives in our hands: Visual inspection, e.g., with a stereo microscope or a reversed eyepiece, helps ensure there is no oil residue remaining and no major damage to the front element. Wearing gloves, clean with 70% Ethanol wetted lens tissue, then wipe away alcohol residue with a fresh dry piece of lens tissue. Wear gloves to avoid oil contamination from fingers. Once dry, the front element should look clean with no obvious residue or lint left behind. Reinsert the objective in the microscope turret, ensuring any correction collar is set at the correct value and allow the temperature to stabilise as part of the system warm-up.

Allow the temperature to stabilize.

Note

An important variable that should be regulated, and at the very least recorded, is the temperature. We recommend measuring this each time at the sample stage and the room temperature, as the temperature at the sample affects the RI of the immersion medium and room temperature can affect the scan-head components. The recommended room temperature is 23oC (based upon manufacturer’s recommendations in their technical specifications and the refractive index of most immersion oils (see Figure 2)), but stability is more essential to ensure an accurate z-stack with no thermal drift.

Expected result

Figure 2: Influence of temperature on PSF measurements. The same bead sample was imaged using the same microscope settings (LSM, open pinhole) and Zeiss 518F immersion oil, whose refractive index is optimised for 23 °C. Images were captured using a Zeiss LSM800 attached to an inverted microscope equipped with an incubation chamber (Pecon). A 63x/1.4 objective was used. The microscope incubator was allowed to stabilise for at least one hour after reaching temperature to ensure stability before capturing images. n = 12-20 beads per temperature test. Significant differences observed within each axis as shown (one way ANOVA with post hoc Holm-Sidak Tests, P< 0.05 single asterisk (comparing x values, normally distributed) and non normally distributed Y and Z values tested with Dunn's test, P< 0.05 single asterisk, P< 0.01 double asterisk). Outlying datapoints (<5% and >95%) shown as filled dots.

Find the beads.

Place your sample on the stage with sufficient immersion medium to just allow coverage of the lens's front element once it has made contact with the coverslip.

Focus on the beads using epifluorescence and a filter set matching the fluorescence properties of the beads (i.e. the GFP or FITC filter set) - the focal plane is right at the coverslip-mountant interface. The beads will be denser in certain areas. Focussing in a dense area is easier, so moving the stage in x and y directions while focussing helps.

Note

While the beads used here give a strong signal and should be easily visible through the oculars, inexperienced users may find it difficult to find them, and focussing on bubbles within the mounting with a lower magnification objective first may help.

Move to an area where beads are sparse and ensure you have at least one bead in the centre of the Field of View (FoV), with none too near to each other so that overlapping PSF patterns are avoided. We recommend a spacing at least 4 μm between neighbouring beads.

Note

Any clusters of very close together beads will appear as 'single' bright beads- avoid these and choose the dimmer beads.

Acquisition settings

Where possible, set the confocal "zoom" to use the centre of the FoV.

Note

We recommend at least a 2x zoom and field sizes between 10 x 10 μm to 30 x 30 μm.

Ensure at least one bead is in or near the centre of the FoV.

Note

30 x 30 μm equates to approximately a 2.5 x zoom with a 63 x lens, which can be used to capture 4 to 6 beads with good separation whilst avoiding having beads near the edges of the FoV (Figure 3).

Expected result

Figure 3: Maximum Intensity Projection (MIP) processed from z-stack images of fluorescent beads recorded with a confocal microscope and a 63x/ 1.4 NA objective. The FoV is 22 x 22 μm, and the green ROI square highlights the beads that are selected for the FWHM calculation later on (see Appendix 3).

Set the capture parameters to achieve a voxel size of 40x40x100 nm for objectives with NA>1.3 (see Figure 4).

Note

On an LSM, one may adjust the frame size in pixel number and/or zoom into the sample to fulfill the Shannon-Nyquist criterion (see next Note). On a spinning disk system, we are limited by the camera pixel size and objective magnification. For instance, for a 40x/ 1.3 objective and for a large pixel detector (e.g. EMCCD camera with 16 μm pixel size) the corresponding pixel size becomes 400 nm, far from fulfilling the Shannon-Nyquist pixel size of 171 nm. In that case, one should note the discrepancy. Precise PSF measurements are not possible, but one can monitor the PSF of the objective over time for the Quality Control (QC) of the instrument.

Note

Whichever voxel sizes are chosen, it is essential to fulfil the Shannon-Nyquist criterion.The pixel size should be smaller or equal to half the expected resolution of the optical system. When not possible, one should note the discrepancy. Always ensure that the same voxel sizes are maintained between tests to allow direct comparison of FWHM estimates over time.

CITATION

CITATION

CITATION

CITATION

Expected result

Figure 4. PSF dependence on the sampling rate on a LSM microscope (open pinhole). A. Dependence of the mean FWHM along the x and y axis with the pixel size. B. Dependence of the FWHM along the z axis with the z step. Significance was evaluated using the unpaired ordinary one-way ANOVA test followed by Dunnett’s multiple-comparisons test setting the 80 nm lateral and 200 nm axial voxel sizes as controls. A p-value < 0.05 (marked with *, when p<0.0001 then it is marked with ****, and when p>0.05 then it is not significant marked with "ns") was considered statistically significant (normal distributions). The number of tested beads (175 nm size) for all voxel size cases was in the range of 35-50. A 63x/1.4 objective was used on a LSM880 (Zeiss) microscope and the signal was acquired in the GFP channel. We observe that for a voxel size of 80x80x200 nm or lower there is no significant difference in the measured FWHM. Decreasing the voxel size more than 40x40x100 nm does not improve measurement precision of the FWHM and can induce bleaching of the sample and worse SBR.

Note

If desired, the data can be captured with voxel sizes, up to 80x80x200 nm in xyz. This value is sufficient for routine QC measurements and gives a precise estimation of the FWHM. For measuring the microscope PSF performance and for deconvolution studies, a slight oversampling is recommended and thus the voxel value of 40x40x100 nm.

On LSMs, keep the pinhole wide open.

Note

An open pinhole allows one to detect aberrations more easily. While this is not useful for deconvolution, it is more beneficial for QC and monitoring.

Note that when opening the pinhole, the bead Airy disk intensity should not significantly change. If this is the case, the pinhole is misaligned and should be adjusted.

Using a live image, optimise the laser power (the 488 nm line is recommended for the beads used here) and the detector gain to obtain a reasonable signal with a minimum background such that the detected noise is not clipped at zero. Set image acquisition parameters to capture in single direction mode and use averaging or increased pixel dwell time to improve signal to background ratio (SBR). Adjust the focal plane for the maximum intensity. Ensure that no bleaching of the beads occurs by decreasing the laser power and no pixel saturation, by if needed changing the detector gain.

Note

Note on Signal. A good rule of thumb to avoid saturation and ensure you see as much of the airy disks as possible is to set the bright centre of the bead to report pixel values of 200 if in 8-bit mode or 3,500 for 12-bit mode.

Note

Note on PMT offset. Offset is a discriminator for adjusting how much of the electronic signal emanating from the PMT is treated as true signal and not background system noise. PMT offsets are set by the engineer to ensure that at 0 or 1 (depending on software) they report no/little signal with no light in the system. As such, the offset should not be adjusted when capturing images: one should use laser power and detector gain only to increase or decrease signal, only using offset to ensure that only a small non zero background is detected. If this isn't the case, ensure you set the offset so that no pixels read zero values at the central focal plane. GaAsP based detectors, including hybrid (HyD) detectors, are sensitive enough to detect single photons, and as such zero pixel values are true zero values and can be accepted.

Note

To test for bleaching you can for example acquire two consecutive z- stacks of the same FoV. Comparing maximum projections of the two stacks should show little difference in intensities. For the beads we tested, there is little chance of this being a problem, as they are bright and stable, requiring low excitation power.

Using the z focus drive (ideally a piezo drive if available), ensure you are at the axial centre of the bead (select for the widest and brightest signals). Set the z stack to capture 5 μm with a stepsize of 100 nm (51 slices) minimum using the centre of the bead as the centre of the stack (See Figure 4 for justification of axial sectioning).

Note

If desired, the data can be captured with larger voxels, up to 200 nm in z (25 slices).

Capture images of multiple beads (at least 6, ideally 20).

Note

More beads give a more accurate result with lower error, mostly due to variations from bead to bead.

Note

Beads have to be well separated such that they keep a mutual distance of at least ten FWHM along all dimensions.

Note

Check that the captured images contain all of the data (the centre of the beads should be approximately in the middle of the stack, and at the end of the stack on each side, there should be very little to no signal) and drift did not occur. Most confocal systems return to the mid focal plane once the image acquisition is finished. Check that this is the case and that the central focal plane is still optimally in focus. If not, then focal drift has occurred during image acquisition and the PSFs will be incorrect. Re-centre the stack and repeat once you think temperatures have stabilised.

Bead Analysis

Bead Analysis

Bead analysis consists in measuring the FWHM of the acquired PSFs. First one has to choose the analysis software.

Note

Images can be analysed with several software packages (see Table 2 for the existing open source or commercial software).

Note

As an example, we describe in Appendix 3 analysis using MetroloJ_QC (https://github.com/MontpellierRessourcesImagerie/MetroloJ_QC), which is a plugin for ImageJ/ Fiji (https://imagej.nih.gov/ij/ and www.fiji.sc) that can analyse various QC measurements.

CITATION

Expected result

| A | B | C | D | E | F | G | |

| Software | Open Source | Multiple Images | FWHM Method | Background Estimation | Multiple OSs | r2 Fitting | |

| Daybook | No | Yes, with subscription | Gaussian, sech2, Lorentzian | Yes | No | Yes | |

| MetroloJ-QC | Yes | Yes | Gaussian | Yes | Yes | Yes | |

| Napari-PSF-Analysis | Yes | No | 3D and 1D Gaussian | Yes | Yes | Yes | |

| PSFDistiller | Yes | No | 2D Gaussian (xy) | Yes | Yes | Yes | |

| PSFj | Yes | Yes | 2D Gaussian (xy), 1D (z) | Yes | Yes | Yes | |

| PyCalibrate | Yes | Yes | 2D Gaussian (xy), 1D (z) | No | Yes | Yes | |

| SVI Distiller | No | Yes | none, Gaussian, Lorentzian, Pseudo-Voigt, Pearson | Yes, manual | Yes | No |

Table 2. Common software packages for PSF analysis with their characteristics. Software tested: Daybook 3: https://argolight.com/document-and-share-results-with-daybook-software/ , MetroloJ_QC: https://github.com/MontpellierRessourcesImagerie/MetroloJ_QC , MIPs for PSF: GitHub - fmi-faim/napari-psf-analysis, PSFDistiller: https://github.com/bionanoimaging/PSFDistiller.jl, PSFj: https://biii.eu/psfj (https://www.nature.com/articles/nmeth.3102), Pycalibrate: https://www.psfcheck.com/psfcheck-processing , SVI Distiller: https://svi.nl/Huygens-PSF-Distiller.

Each analysis software may use a different fitting method of the PSF. Most software packages use a 1D or 2D Gaussian fit. Although confocal PSFs can be sufficiently fitted by a Gaussian function, the fitting method is crucial for an accurate measurement of the FWHM and thus the assessment of the objective performance.

CITATION

For monitoring the performance of the objective over time, using the same protocol (sample preparation, acquisition and analysis software) is mandatory.

Note

If there are large flaws in the system, then the different fitting methods may produce different results (see Appendix 1).

Note

For PSF characterization a qualitative check 'by eye' is essential in case there are optical aberrations of the system. The measured FWHM values can sometimes not reveal the flaws in all directions, depending on the fitting algorithm of the software (see Appendix 1).

Before analyzing the images visually inspect the acquisitions. Some images need to be cropped to remove saturated beads. An alternative option can be used to automatically discard any saturated beads from the image, if the analysis software offers this option.

To measure the FWHM, the software package needs to read the image metadata, such as the voxel size. This can be done directly or has to be inserted manually, depending on the software. The software may then need the user to insert other parameters, like the objective numerical aperture, the excitation-emission wavelengths, the pinhole size, the bit depth, among others, for different metrics calculations. The software may then allow a batch analysis of multiple images and multiple acquisitions and provide an average FWHM.

Here is a common result of an analysis software (MetroloJ_QC) for a FWHM calculation of one bead.

The most important parameter to be calculated is the FWHM along the xyz dimensions. Other information, such as the SBR, the lateral asymmetry ratio (LAR) or the goodness of fit r2 can be provided by the software.

Figure 5: PSF analysis of one bead by MetroloJ_QC plugin. Orthogonal projection of one bead helps visualize the PSF and detect aberrations. The FWHM along x, y, and z of the bead is measured (in μm) along with the calculated goodness of fit (r2), the XY asymmetry (LAR) and the SBR.

Note

We recommend to keep calculated FWHM values with a Gaussian goodness of fit r2 value superior to 0.95.

The analysis method is up to the user. We recommend to at least plot the data as box and whisker plots and to keep track using Excel, Airtable, OMERO, or other suitable software. KNIME for example, can be used to track output from PSFj over time to monitor a system's performance.

CITATION

Appendix 1: Aberrations and PSF

Appendix 1: Aberrations and PSF

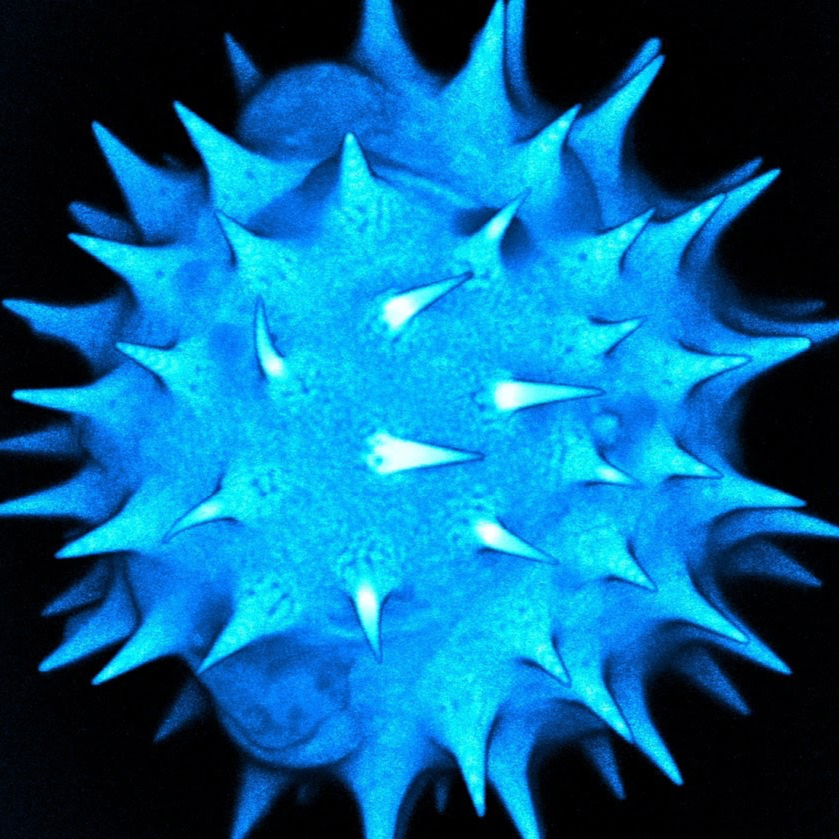

Aberrations reduce the resolution and sensitivity of a light microscope. Careful inspection of the collected PSF can help to identify potential aberrations causing poor microscope performance. Examples of common aberrations are shown in Table 1.

Expected result

Table 1: Summary of the most common aberrations encountered in light microscopy. Also includes examples of each aberration imaged using (top-bottom) LSM, astigmatic Single Molecule Localisation Microscopy (SMLM), point scanning confocal, spinning disk confocal and spinning disk confocal respectively. The tilt example is taken from a single imaged bead, the astigmatism example is processed from raw data supplied in (Li, et al., 2018), the other examples are several (~5) beads averaged using PYME (https://python-microscopy.org/). Scale bar: 1μm.

CITATION

Note

Here we have described the aberrations by common names. Aberrations are usually described in relation to the wavefront at the back focal plane of the objective. This can be decomposed into a series of Zernike polynomials of varying orders.

CITATION

Figure1: Influence of the analysis software on the FWHM measurement of the PSF. A. Orthogonal view of the PSF of one bead acquired with a spinning disk and a 60x/1.42 objective (GFP channel). MetroloJ_QC and PSFJ software analysis showed similar results on the FWHM calculations and xy Asymmetry (LAR) metric. B. Same bead of (A) rotated 45 degrees and reanalysed. Discrepancies are found in the FWHM values and LAR. The reason is that MetroloJ_QC calculates the lateral FWHM among the x and y axis as defined on the image, while PSFJ considers the min and max value for the two lateral dimensions. There is no 'bad' way of calculating the FWHM, it all depends on what one is studying.

Appendix 2: Tutorials

Appendix 2: Tutorials

MetroloJ_QC manual:

PyCalibrate manual and video tutorial:

Appendix 3: MetroloJ_QC analysis method

Appendix 3: MetroloJ_QC analysis method

Here we provide instructions for running MetroloJ_QC in Fiji, since Fiji comes with the Bioformats plugin automatically installed, allowing easy import of raw images.

Open Fiji and then start the MetroloJ_QC plugin from the Plugins menu.

Run either the single image PSF calibration (Figure 1, blue arrow) or the batch multi image option (green arrow), which will process all images in a directory.

Expected result

Figure 1. MetroloJ_QC graphical user interface running with Fiji. the blue arrow highlights the PSF measurement software and the green arrow shows the multiple image PSF measurement software.

Note

Running the single image or batch loader provides an output as a CSV file and a PDF report containing the data from all analysed beads. We recommend using a database for storing these data for each objective and microscope combination so that they can be compared over time as a simple way of tracking potential problems.

Running the batch option will ask for a directory- select the directory containing the raw image files.

Most of the metadata should be imported correctly from raw microscope files (voxel size), but parameters should be double checked and missing values entered manually, such as the excitation/emission wavelengths, the objective NA, the image bit depth, or the pinhole size. Several parameters are variable depending on your preferences and dataset, such as whether to discard saturated beads (recommended), the prominence value (important for properly thresholding and taking into account all the beads) and the ROI around the bead (Figure 2). If beads are closer than the given ROI, then the beads are discarded.

Figure 2: Parameters window. Some of the metadata are read directly from the image (voxel size) and others have to be filled in manually (wavelength, NA, pinhole). The user should fill in the bead analysis parameters, like bead size, ROI around the bead, and prominence value.

The plugin calculates the FWHM along the x, y, and z-axes of all beads in the field of view. FWHM is measured as follows: the maximum intensity pixel within the entire 3D data set is determined. An intensity plot along a straight line through this maximum intensity pixel point is extracted in all dimensions. The curves are fitted by a Gaussian function using the built-in ImageJ curve fitting algorithm to determine the FWHM. After automation of the FWHM measurements on several beads/datasets, average values are extracted in all three dimensions, and standard deviations are calculated. In case the algorithm detects spots that do not originate from the beads, they can be removed using the fitting parameter r2.

Upon completion, the batch PSF tool will leave the found bead co-ordinates from the last image in the directory showing in the Results table. Navigate to the folder of raw images and you will find a new sub-directory structure with summary csv files (.xls), a pdf and individual bead data.

Figure 3: Directory structure produced for the processed images in Batch mode from MetroloJ_QC

The summary.xls file contains the means, SDs and SBRs for all three axes, plus the individual bead FWHM and goodness of fit (r2).

Figure 4: Example csv file (summary.xls) output from running MetroloJ_QC in batch mode. The first rows give the average for the 3 dimensions, followed by rows with the individual bead FWHM (column B) and goodness of fit (r2, column C) in each dimension.

The plugin calculates two QC metrics. The first one is the measured to theoretical FWHM ratio. If the ratio is greater than the value indicated as tolerance value in the metadata and plugin parameters step (step 33) then the value appears in red. If the value is within recommendations, it is highlighted in green. The second parameter is the Lateral Asymmetry Ratio (LAR), defined as the ratio of the minimal to the maximal xy FWHM value.

Figure 5: Summary output metrics from MetroloJ_QC.

Citations

Step 10

Zhang B, Zerubia J, Olivo-Marin JC. Gaussian approximations of fluorescence microscope point-spread function models

Step 14

Klemm AH, Thomae AW, Wachal K, Dietzel S. Tracking Microscope Performance: A Workflow to Compare Point Spread Function Evaluations Over Time.

https://doi.org/10.1017/S1431927619000060Step 3

Cole, R., Jinadasa, T. & Brown, C. Measuring and interpreting point spread functions to determine confocal microscope resolution and ensure quality control

https://doi.org/10.1038/nprot.2011.407Step 3

Demmerle J, Innocent C, North AJ, Ball G, Müller M, Miron E, Matsuda A, Dobbie IM, Markaki Y, Schermelleh L. Strategic and practical guidelines for successful structured illumination microscopy

https://doi.org/10.1038/nprot.2017.019Step 6.2

Theer P, Mongis C, Knop M. PSFj: know your fluorescence microscope.

https://doi.org/10.1038/nmeth.3102Step 8.3

Pawley JB. Points, Pixels, and Gray Levels: Digitizing Image Data

10.1007/978-0-387-45524-2_4Step 8.3

Heintzmann R, Sheppard CJ. The sampling limit in fluorescence microscopy.

Step 8.3

Scriven DR, Lynch RM, Moore ED. Image acquisition for colocalization using optical microscopy.

https://doi.org/10.1152/ajpcell.00133.2008Step 9

Faklaris, Orestis, Bancel-Vallée, Leslie, Dauphin, Aurélien, Monterroso, Baptiste, Frère, Perrine, Geny, David, Manoliu, Tudor, de Rossi, Sylvain, Cordelières, Fabrice P., Schapman, Damien, Nitschke, Roland, Cau, Julien, Guilbert, Thomas. Quality assessment in light microscopy for routine use through simple tools and robust metrics

https://10.1083/jcb.202107093